There are two main criteria for choosing an adhesive for laminated veneer lumber (LVL) – strength and sustainability. This is why we choose OSHIKA P.I. BOND PI-5340_S2. adhesive.

We use OSHIKA’s Aqua PUI water-based polymer-urethane isocyanate adhesive (Japan) for the production of walls for our houses.

We use OSHIKA’s Aqua PUI water-based polymer-urethane isocyanate adhesive (Japan) for the production of walls for our houses.

The two-component adhesives were invented in Japan and later expanded to Europe and globally. Today, the PUI adhesives are widely used for load-bearing and non-load-bearing structures under the strict requirements of the Japanese standards such as JAS MAFF1152, JIS K 6852 & K 6806.

- Compliance with the stringent requirements of the Japanese standards JAS [1] MAFF 1152, JIS [2] K6852 & K 6806 class 1 for laminated veneer lumber

- Suitable for spruce, pine, cedar, larch, etc. (including "difficult” species)

- It is used for gluing "on the face” and may also be used for mortise-and-tenon joints, etc.

- Suitable for cold and hot pressing and may also be used in HFC presses

- PH-neutral, preventing the glue line staining

- Phenol-free

- Formaldehyde-free; complies with F **** Cert. No JAIA-012382

- Non-flammable (due to the increased heat resistance)

- Ensures high water resistance for non-structural glued hardwood lumber

[1] Japaneese Agricultural Standard

[2] Japan Industrial Standards

Learn more

According to the tests that were conducted by an accredited laboratory of the Russian Service for Customer Protection and Wellbeing, Japanese OSHIKA P.I. BOND PI-5340_S2 adhesive has not been classified as hazardous to human health or the environment. The cured product does not contain phenol or formaldehyde, is chemically neutral, and does not emit any odors or toxic compounds.

According to the tests that were conducted by an accredited laboratory of the Russian Service for Customer Protection and Wellbeing, Japanese OSHIKA P.I. BOND PI-5340_S2 adhesive has not been classified as hazardous to human health or the environment. The cured product does not contain phenol or formaldehyde, is chemically neutral, and does not emit any odors or toxic compounds.

Glued wooden structures manufactured using this Japanese adhesive comply with all applicable health & safety requirements. This adhesive complies far beyond the environmental standards in the field of residential building materials – even in Japan which has the world's most stringent environmental regulations.

In mid-2020, OSHIKA CORPORATION signed an agreement with Kucherenko Structural Engineering R&D Institute (Russia) and began work on the Russian certification testing of P.I. BOND PI-5340S, PI-5340_S2, and PI-3210_S3 for compliance with functional classes 2b and 3 of Glued Laminated Timber (Glulam), as well as long-term testing of the adhesives for compliance with 1a, 1b and 2a functional classes of Glulam under Russian standard GOST 20850-2014.

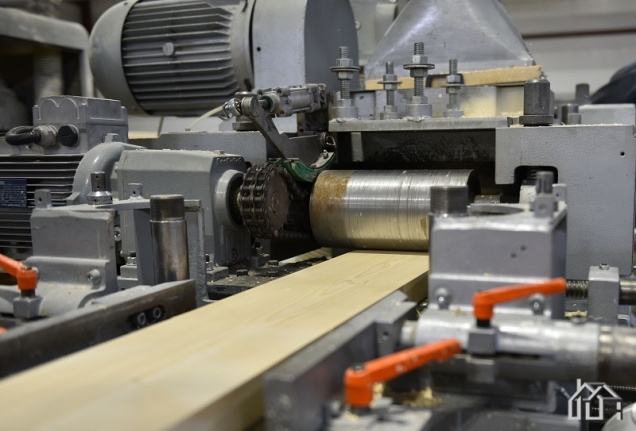

In LVL manufacturing, we use no.1 and no. 2 (AB) grade spruce in accordance with GOST (State Standard) 8486-86 (

In LVL manufacturing, we use no.1 and no. 2 (AB) grade spruce in accordance with GOST (State Standard) 8486-86 (